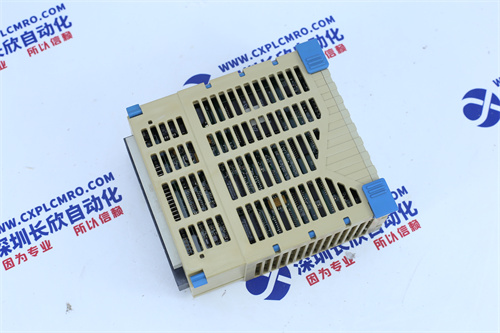

BENTLY 3500/20

The BENTLY 3500/20 Vibration Monitoring and Analysis System module is an advanced module for vibration monitoring and fault diagnosis of rotating machinery. It combines advanced vibration sensors and signal processing technology to monitor and analyze the vibration state of rotating machinery (such as turbines, generators, compressors, etc.) in real time. The module provides rich vibration data monitoring, trend analysis, fault warning, and report

generation functions to help users accurately judge equipment health status, predict potential faults, and take appropriate maintenance measures. The BENTLY 3500/20 module is suitable for a variety of industrial applications and provides a strong guarantee for the reliable operation of rotating machinery.

generation functions to help users accurately judge equipment health status, predict potential faults, and take appropriate maintenance measures. The BENTLY 3500/20 module is suitable for a variety of industrial applications and provides a strong guarantee for the reliable operation of rotating machinery.

Product parameters:

Monitoring parameters: vibration speed, displacement, acceleration, etc

Sensor type: Support a variety of vibration sensors, such as accelerometer, speedometer, etc

Sampling frequency: high-speed sampling to ensure data accuracy and real-time

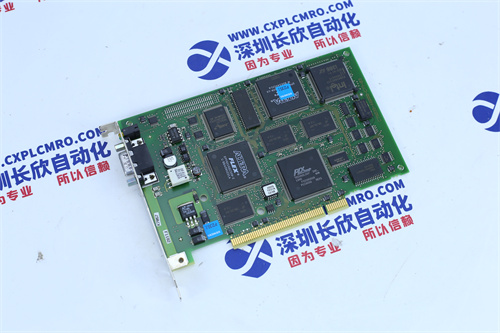

Data processing: Advanced signal processing technology provides accurate vibration analysis and fault diagnosis

Alarm function: Support multi-level alarm threshold setting, timely vibration abnormal alarm

Data storage: Built-in storage function to support long-term vibration data recording

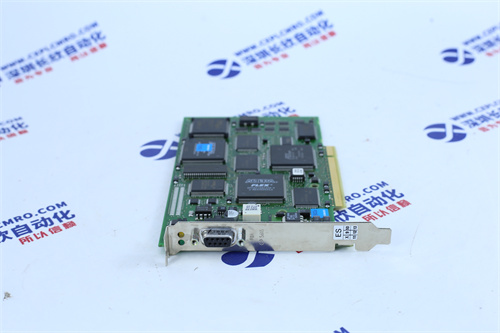

Communication interface: supports a variety of industrial communication protocols to facilitate remote data transmission and system integration

Report generation: Automatic generation of vibration monitoring reports, providing comprehensive data analysis and diagnostic information

Specifications:

Size: Compact design to accommodate various installation space requirements

Weight: Light and easy to install and maintain

Operating voltage: Wide voltage range, adapt to different industrial power environment

Operating temperature range: suitable for a wide range of industrial ambient temperatures

-300x300-c.jpg)

Reviews

There are no reviews yet.