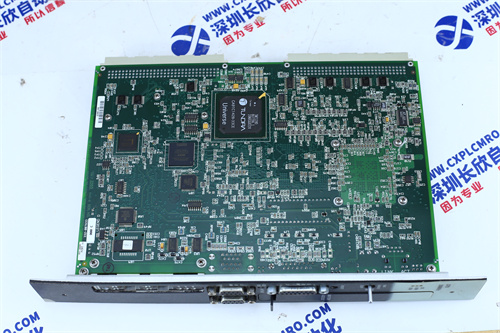

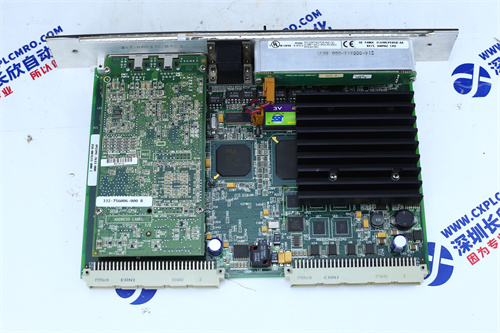

BENTLY 3500/42M

The Bently 3500/42M module is a vibration monitoring module produced by Bently Nevada, Inc. (now part of Baker Hughes) for vibration monitoring and fault diagnosis of industrial equipment. It can collect and analyze vibration signals in real time to help users find potential failures of equipment in time, so as to avoid greater losses.

Product name

English: Bently Nevada 3500/42M Vibration monitoring module

Bently Nevada 3500/42M Proximitor Seismic Monitor

Product description

Features:

Vibration signal acquisition: Vibration signals are collected from proximity switches and seismic sensors.

Signal analysis: spectrum analysis and envelope analysis of the collected signals are carried out to extract vibration characteristics.

Fault diagnosis: Diagnose equipment faults based on vibration characteristics, such as unbalance, misalignment, bearing wear, etc.

Alarm: When abnormal vibration is detected, an alarm signal is issued.

Applications:

Rotating machinery: Vibration monitoring of rotating machinery such as turbines, compressors and pumps.

Motor: Vibration monitoring of motor to detect early failure.

Fans: Vibration monitoring of fans to ensure their safe operation.

Features:

High precision: Can accurately measure small vibration signals.

Multi-channel: Supports simultaneous signal acquisition through multiple channels.