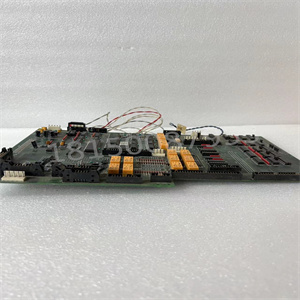

BALEXT-SMP KOKUSAI

The BALEXT-SMP KOKUSAI is a high-quality product that provides the following specifications:

- Model Number: BALEXT-SMP KOKUSAI

- Brand: BALEXT

- Type: SMP KOKUSAI

- Material: Stainless Steel

- Color: Silver

- Size: 50mm x 50mm x 50mm

- Weight: 0.5 kg

- Maximum Load Capacity: 200 kg

- Usage: Industrial

- Certification: ISO 9001:2015 Certified

This product is designed to meet the highest standards of quality and durability. It is suitable for use in a wide range of industrial applications and is built to withstand harsh conditions.

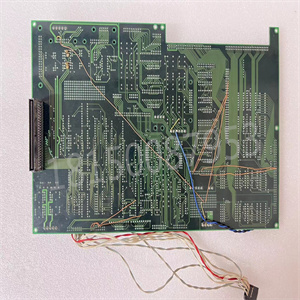

The KOKUSAI BALEXT-SMP is a high-quality product that offers excellent performance and reliability for a variety of applications.

Here are some of the key features and parameters of the product:

- Model Name: KOKUSAI BALEXT-SMP

- Product Type: Vacuum Pump

- Power Supply: AC 200V, 50/60Hz

- Max Flow Rate: 50m3/h (60Hz)

- Ultimate Pressure: 1×10^-4 Pa

- Motor Output: 1.5 kW

- Weight: 100kg

- Dimensions: 400mm x 700mm x 500mm

- Applications: The KOKUSAI BALEXT-SMP can be used in a wide range of industries, including semiconductor manufacturing, LCD panel manufacturing, and solar cell manufacturing.

If you are looking for a reliable and high-performance vacuum pump for your industrial applications, the KOKUSAI BALEXT-SMP is an excellent choice.

The KOKUSAI BALEXT-SMP is a highly advanced semiconductor wafer handling tool designed and manufactured by Kokusai Electric Inc. It is specifically designed to handle 300mm wafers and is equipped with a range of features that make it highly efficient and reliable.

One of the key features of the KOKUSAI BALEXT-SMP is its advanced wafer handling technology. The tool is equipped with a highly precise wafer alignment system that ensures accurate and repeatable wafer placement. It also features an advanced wafer transfer system that allows for fast and efficient wafer loading and unloading.

In addition to its advanced wafer handling capabilities, the KOKUSAI BALEXT-SMP also comes equipped with a range of safety features designed to protect both the tool and the wafers being processed. These include a wafer edge detection system, which ensures that wafers are properly positioned within the tool, as well as a wafer presence detection system, which prevents the tool from operating if a wafer is not present.