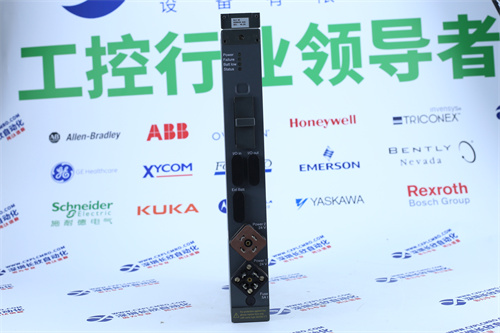

BENTLY 135489-03

The BENTLY 135489-03 bearing condition monitoring module is an intelligent device specially designed for the bearing condition monitoring of rotating machinery. The module integrates high-precision sensors, real-time data acquisition system and intelligent analysis algorithm, which can continuously monitor

bearing vibration, temperature, stress and other key parameters, and provide real-time monitoring, fault diagnosis and early warning functions of bearing status through data analysis and processing. This is of great significance for timely detection of bearing faults, extension of bearing service life, and improvement of equipment reliability and maintenance efficiency.

bearing vibration, temperature, stress and other key parameters, and provide real-time monitoring, fault diagnosis and early warning functions of bearing status through data analysis and processing. This is of great significance for timely detection of bearing faults, extension of bearing service life, and improvement of equipment reliability and maintenance efficiency.

Product parameters:

Monitoring parameters: bearing vibration, temperature, stress, etc

Sampling frequency: Multiple sampling frequency Settings are supported to meet different monitoring requirements

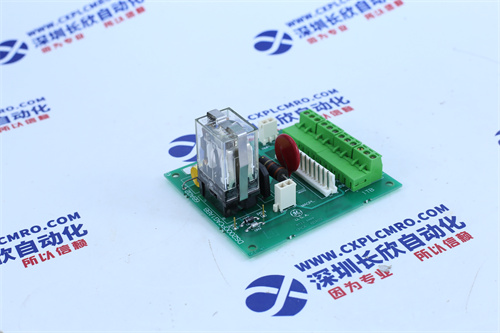

Monitoring channel: Multi-channel monitoring simultaneously, supporting different types of sensors

Fault diagnosis: Provides spectrum analysis, time domain analysis, waveform analysis and other functions to assist users in fault diagnosis

Early warning function: According to the monitoring data, provide bearing failure early warning to remind users to deal with it in time

Data storage and communication: Supports long-term data recording, provides a variety of data storage formats and communication interfaces

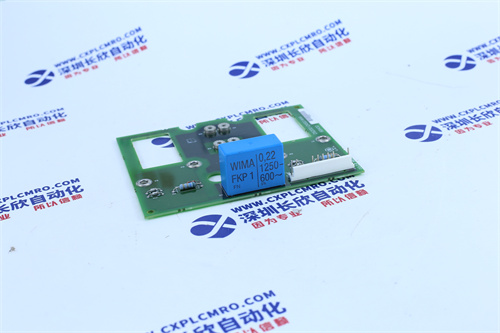

Specifications:

Size and weight: Compact and lightweight, suitable for all installation environments

Working environment: suitable for a wide range of industrial environments, can operate stably under harsh conditions

Power requirements: Standard industrial power input, adapt to different power supply conditions

Protection level: In line with industrial standards, to ensure long-term stable operation of equipment

Certification and standards: Compliance with relevant international and domestic industry standards and certifications

Reviews

There are no reviews yet.