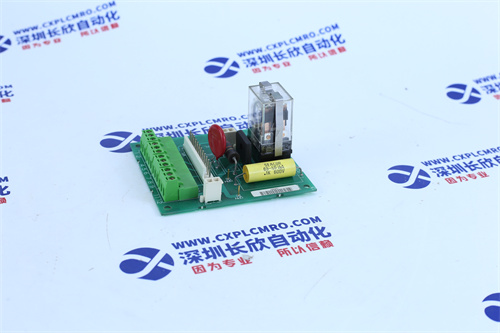

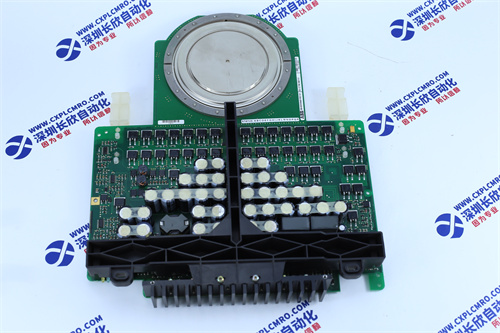

BENTLY NEVADA 330130-080-00-00

The BENTLY NEVADA 330130-080-00-00 Bearing Condition and Vibration monitoring module is an advanced system designed specifically for bearing condition monitoring and vibration analysis of rotating equipment. The module combines high-precision vibration sensors, bearing diagnosis algorithms and powerful data processing capabilities to monitor bearing vibration status in real time, provide early warning of bearing wear, loosening, imbalance and other problems, and help users take timely maintenance measures to prevent equipment failures.

Product parameters:

Monitoring parameters: bearing vibration, speed, temperature, etc

Sampling frequency: high-speed sampling to ensure real-time and accurate data

Monitoring range: Suitable for a variety of bearing types and sizes

Fault diagnosis: Provide diagnosis and analysis of bearing wear, loosening, unbalance and other problems

Data recording and storage: Supports long-term data recording and provides detailed data storage and reporting functions

Communication and integration: Support for standard communication protocols for easy integration with other monitoring systems and equipment

Specifications:

Size and weight: Compact design for a variety of installation environments

Working environment: suitable for a wide range of industrial environments, can operate stably under harsh conditions

Power requirements: Standard industrial power input, adapt to different power supply conditions

Protection level: In line with industrial standards, to ensure long-term stable operation of equipment

Certification and standards: Compliance with relevant international and domestic industry standards and certifications

-300x300-c.jpg)

Reviews

There are no reviews yet.